I'm working on a (currently only conceptual) design for a Peltier-cooled sample holder, and the cold side will need some insulation. It's likely to be a rather complex shape, so 3D printing it looks like a good plan. I can get parts made on a Ultimaker (not sure which model at the moment), normally in PLA.

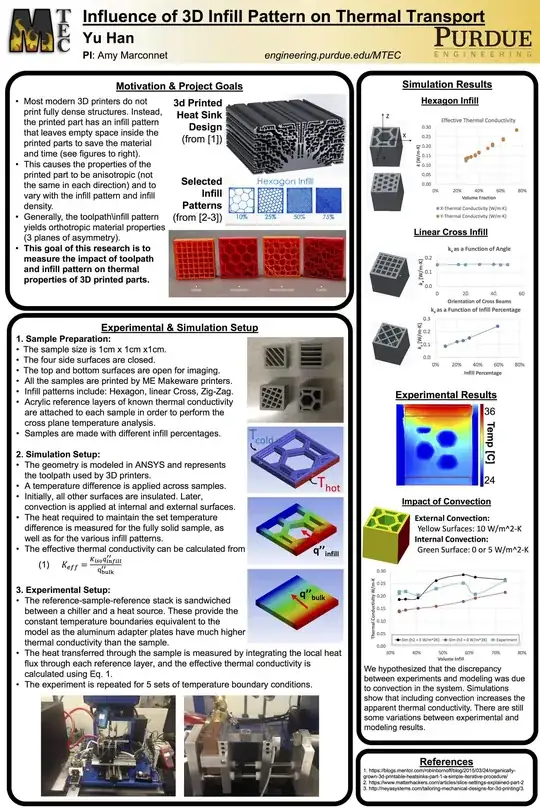

I can look up the bulk thermal conductivity of PLA (it seems to be the best of the typical filaments already. I can find high-TC filaments. What I can't find is how to design an insulating part. In particular, while a reduced fill will reduce the TC, and the actual percentage might allow a decent approximation to the thermal conductivity in an isotropic structure, it's highly unlikely I'll have an isotropic structure. This means I don't know how well I can approximate the final TC as a percentage of the bulk The fill patterns I've seen (as a part designer, not a printer operator) would likely end up like cells running in the direction I want to avoid heat flow (perpendicular to the Peltier's heat-spreader plates). Knowing the TC, I could calculate the heat flow - I have some background in thermal physics.

Is there any kind of established best practice for designing thermally insulating parts? Any way to approximate the thermal conductivity?