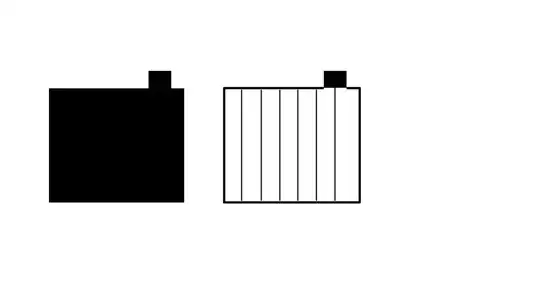

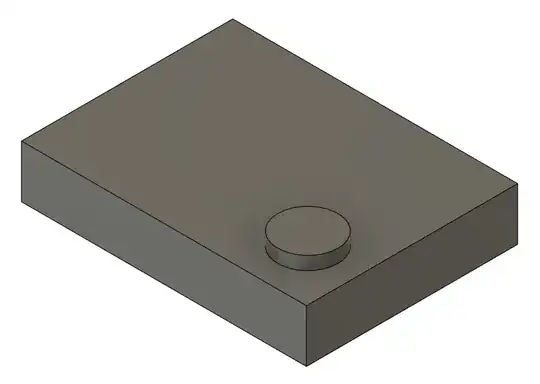

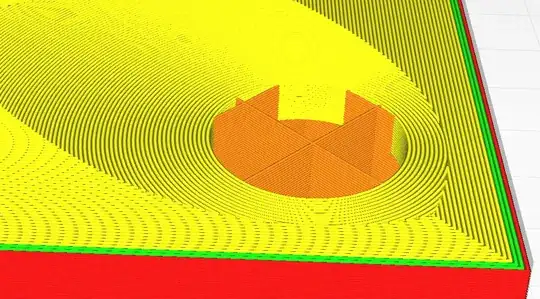

My son is printing a simple block with a small (2 mm high) bump on top - see image below of the cross section. The left shows the 3D model and the right shows where the plastic actually prints, using a grid infill at around 10 %, with a top height of 1.6 mm

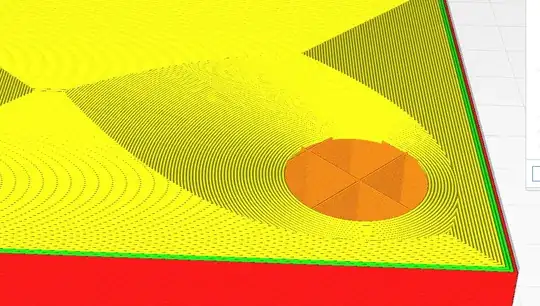

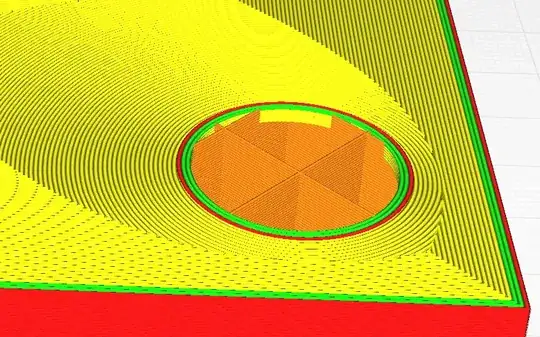

As you can see, this is very weak, and the bump very easily snaps off, as it has very little plastic securing it to the layer below. When we increase the top/bottom thickness (in Creality Cloud) to 4 mm this issue goes away, and the bumps are well connected. But then the print takes a very long time.

Questions:

Is this the expected behavior of a slicer? Why does it not add material to firmly connect the bump to what is beneath it?

How exactly is the "top thickness" setting applied? E.g. if it's set to 2 mm, does that only apply to the layers comprising the topmost 2 mm of the model, or does it stipulate that there must be 2 mm of plastic at the 'top' of the model at all X, Y coordinates?

Is there a way to set the top thickness separately from the bottom thickness in Creality Cloud?