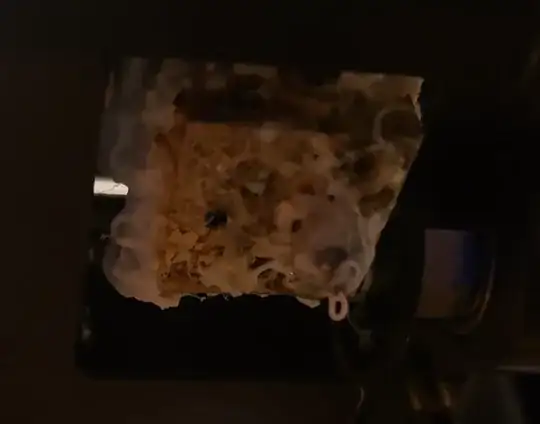

It's difficult to determine if there is anything inside this mass of plastic, but a heat gun applied carefully will allow you to extract it.

When a hot end is assembled, the heat sink (finned cylinder) has a heat break threaded into it (slender metal tube) which then threads into the heater block (block with wires for the heater cartridge and thermistor).

The heater block has the nozzle threaded into it, but it's important to not seat the shoulder of the nozzle on the heater block. Leave a gap of 0.5 to 1.0 mm between the nozzle shoulder and the heater block. Tighten the heat break into the block until it contacts the nozzle. Secure it firmly, but don't snap anything off!

Heat the assembly to the highest safe temperature, between 220 °C and 250 °C and tighten the nozzle again.

Step 7 from cnx-software states the same thing as the paragraph above, but also provides a graphic showing the components:

Your photo shows the results of a nozzle that might have been leaking filament at the top of the nozzle and below the heat break, leaking out of both the top and bottom of the heater block.

Melting the plastic with a heat gun may release the metal components and if you are very careful and very lucky, you won't damage the wiring for the heater cartridge and thermistor. One can expect that the wiring will be damaged, however and you may have to replace the two items. This is advised, as the melted plastic will bond with the wiring and insulation, making it very difficult to manipulate them during assembly.

If you are determined, you won't have to purchase a new hot end and if you have the financial wherewithal, you may want to purchase one anyway.